Increase Your Sales Close Ratio, Reduce Your Sample Waste

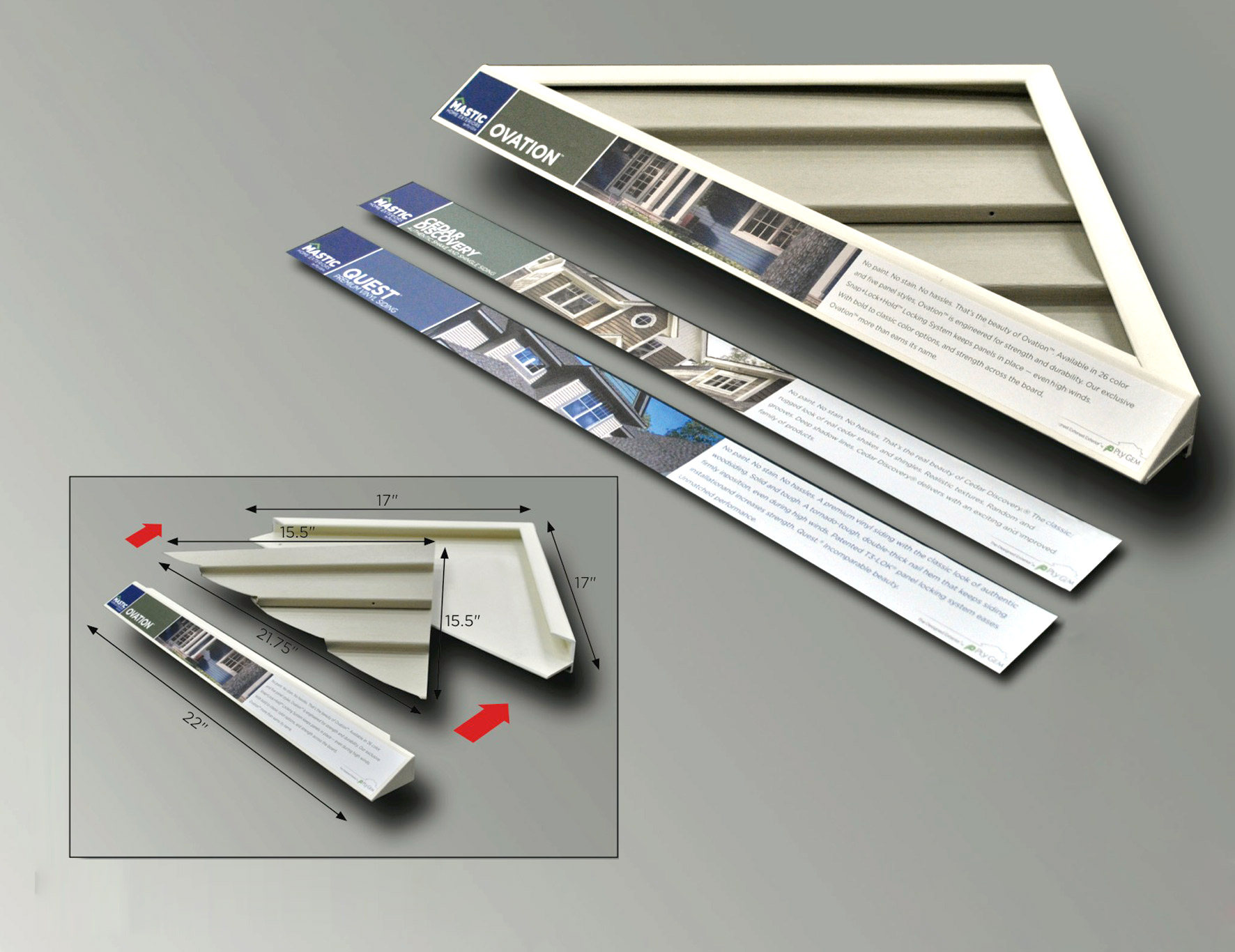

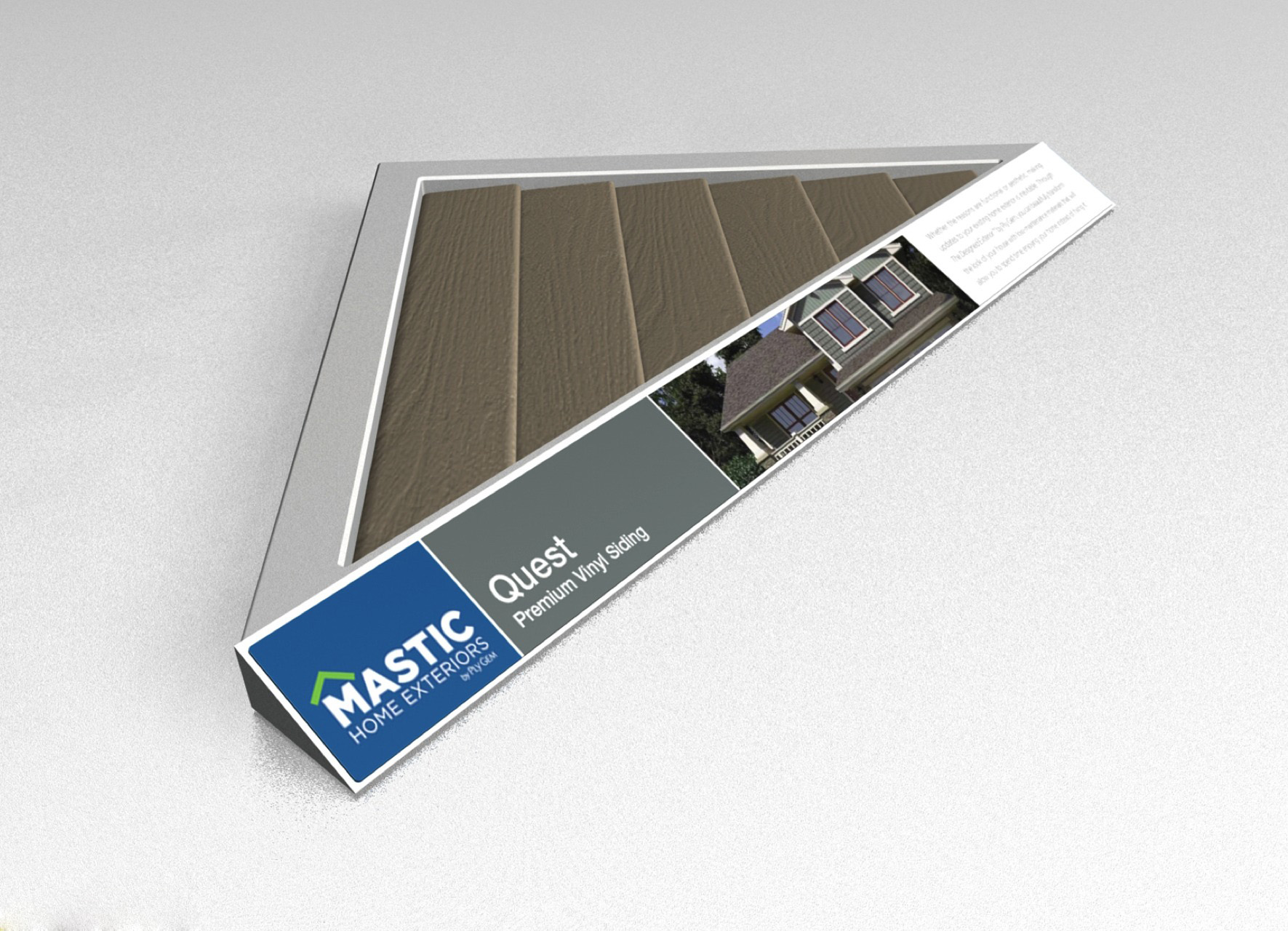

Here’s an example. We were asked to design a new way to present vinyl siding samples and their color palettes, one that better supported the contractor selling process and elevated the homeowner’s experience with the different profiles and shapes. In addition to the creation of the new design, we challenged ourselves to base these on a system of parts that would reduce waste and allow samples to be easily updated. Given the solutions mentioned above, we designed and 3D printed a prototype for a flexible vinyl siding cassette sample holder. Our ideation featured snap-together plastic components that provided a standardized, ready-to-use siding sample for creating alternative product and color options, while in the home. It was also available for pre-purchase in bulk, making it easy to both assemble new samples and update existing ones as product messaging and color palettes changed.

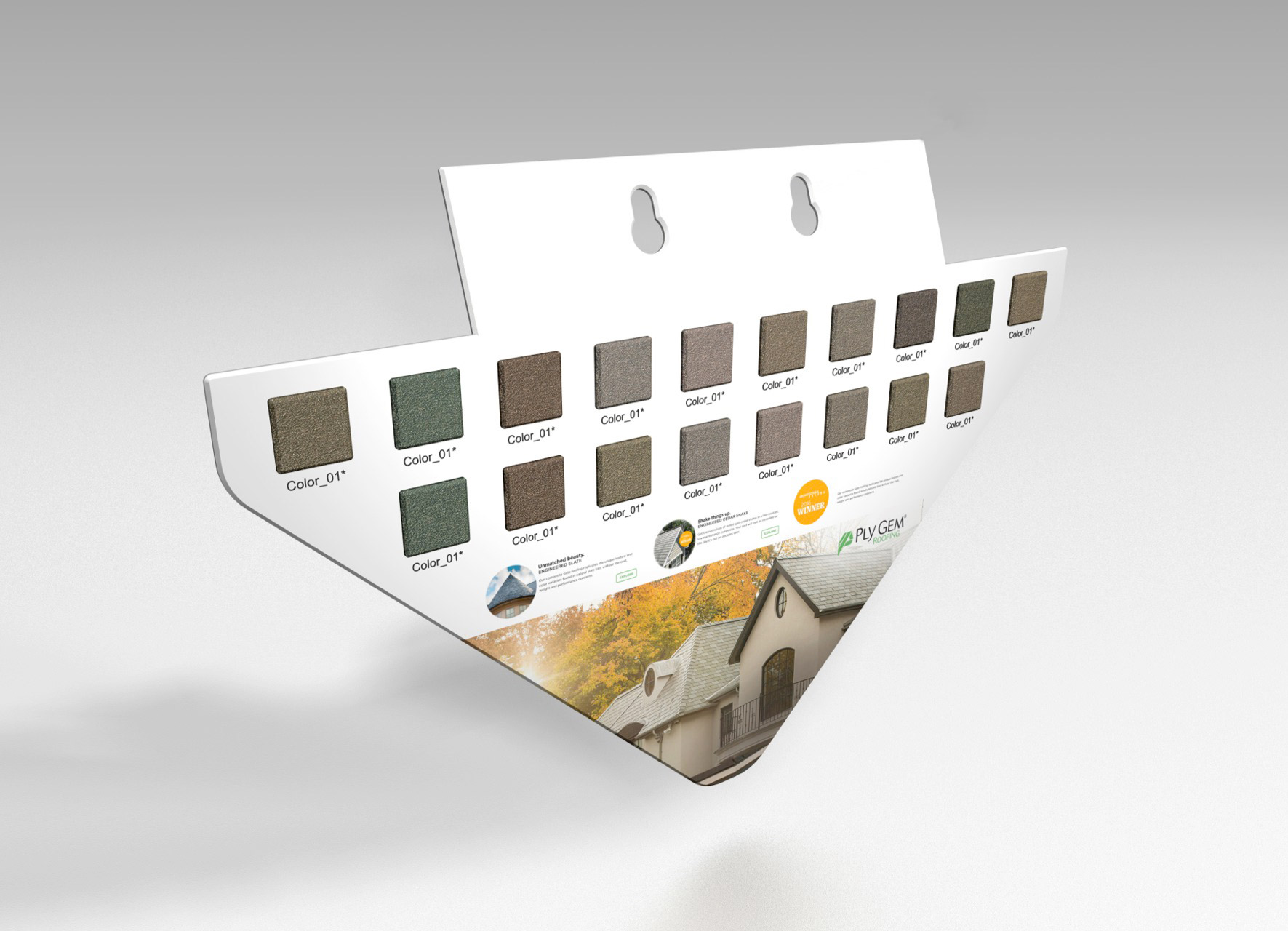

The resulting heavy-duty “siding sample cassette system” organized sample creation and updating. It allowed siding samples to be snapped into a reusable frame, creating an impressive, quality look and feel. A slide-in graphic channel made branding and product stories easy to add and change. An add-on printed color palette with actual siding swatches could be clipped to the back of the sample and folded over to hide it. Our design ultimately improved sample portability and created a professional in home selling tool for the vinyl siding and remodeling contractor.

Prototypes of the cassette system were shared with contractors in several regional focus group, who provided feedback used to affirm and refine the concept prior to launch.